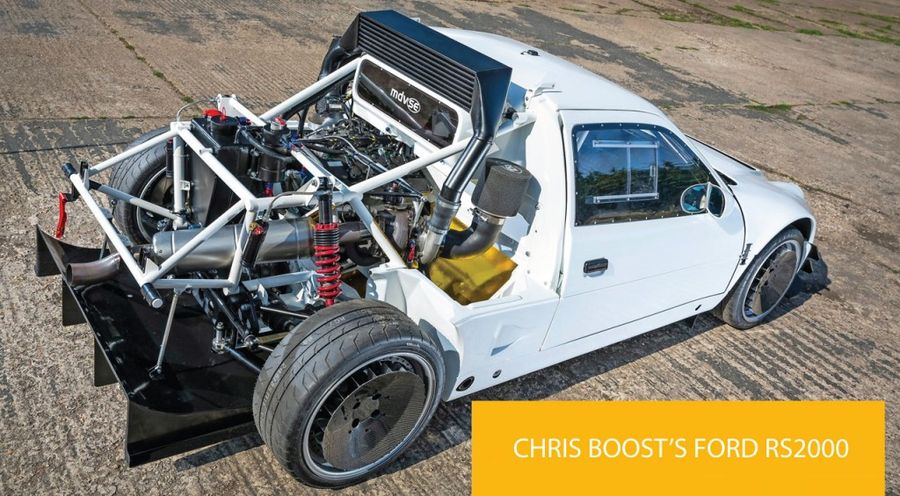

Looking at this quite frankly stunning RS200, you would never believe that just two years ago it was nothing more than a pile of spare parts. But it was. And yet here it sits today – all 700bhp of it – complete with its carbon panels, 21st century suspension, pneumatic paddle-shifted sequential gearbox, and digital dash display lifted from the current Fiesta WRC car. It shows what a modern-day Group B rally car would look like! And clearly has been built to be the ultimate tarmac rally car!

The man lucky enough to own this machine is the rather aptly named Chris Boost , but perhaps a better man to tell the full story behind the build of this seriously fast Ford is the Project Manager, and now it’s complete – the co-driver, Chris Flint.

Chris explains: “Chris (the owner) has been a family friend for over 30 years, and he’s always been a serious pertrolhead. I convinced him to watch a load of YouTube clips of RS200s, and he soon became very keen on acquiring one of his own.”

The problem is, RS200s don’t come up for sale all that often, and when they do you don’t just pick up a copy of your local newspaper and expect to see one in the ‘motors for sale’ classifieds at the back. So the pair put the word about that they were after one.

The best offer, it seemed, was a pile of spare parts - sold under the pretence it was a ‘full car missing a few items’. Chris remembers that this wasn’t exactly the case, and a ‘few parts’ may have been a little optimistic. But nevertheless a deal was done and they soon owned a host of unused RS200 parts.

Sod’s law would have it that no sooner than had they shaken hands on the deal for the ‘kit of bits’, they were offered another RS200 at a very good price – this time an original, registered ‘Evo’ version. “I told the owner that if he could afford to buy it he should, as the Evo would only ever go up in value,” recalls Chris. His advice was followed and the ‘kit of bits’ project was put on the back burner while the pair went rallying in the 600bhp Evo model.

The Evo was awesome fun, but as Chris describes it was a car developed in the 80s predominantly for gravel rallying, and the pair were competing in tarmac rallies. So they had the idea of using the ‘kit of bits’ as a basis to build the ultimate RS200, using modern technology, materials, and processes to bring the 80s monster into the 21st century. “Our plan was to build a modern-day Group B rally car suitable for both road and track use,” smirks Chris.

Chris immediately spoke with the guys at MDV Specialist Engineering in Essex and asked them to undertake the build. As the team behind the awesome Mach 2 Racing Pikes Peak RS200, Chris knew they were more than capable of building the car he

had envisaged.

All the parts that supposedly made for an unassembled car were delivered to MDV’s workshops and the build commenced. The unused tub formed the starting point, and MDV built new front and rear chassis sections to ensure the car would be as strong but as light as possible. In addition to this they fabricated a custom roll cage too, again designed to offer maximum strength and rigidity but without adding excess weight.

Everything in the pile of parts was then thoroughly assessed to see what was useable and what wasn’t – every piece right down to the smallest of clips and brackets was checked. If it made the grade it was fitted during the mock-up stages, if it didn’t, a suitable replacement was sourced. Chris tells us that this often involved redesigning and re-manufacturing parts and making them from scratch, but as he puts it: “at least we will be able to reproduce them if we need any spare parts or for any future builds.”

Once everything was mocked up, it was then stripped down again so it could be sent away for powder-coating before final assembly could begin. Chris admits that supposedly simple jobs like fitting the panels took longer than usual, but this was because the team strived for a much tidier finish than Ford accepted from a rally car

almost 30 years ago. While the car was being assembled, the BDT engine was also getting a new lease of life thanks to Tom Evans and Tommy Field at Field Motorsport. Originally 1804cc, this BDT now features longer I-beam rods, shorter pistons, and a longthrow crankshaft to increase the capacity to 1950cc. This enabled the standard diameter piston and bore size to be retained, and meant the block would require less machining and therefore remain as strong as possible. Chris then specified the turbo – a MAR-M 247-shafted Garrett GT35/T4 hybrid from CR Turbos – while MDV sorted out the electronics – a Life Racing F88 ECU using a fly-by-wire throttle with ‘boost on demand’ system with a bespoke loom from Gary Barker at GTEC – and all the ancillaries.

During the engine build, the team also had to decide on what transmission they wanted to run. “We had a choice of three from the outset, all sequential. A Sadev, a Maktrak, or a Quaife,” explains Chris, “After seeing Pat Doran use a Quaife ‘box at Pike Peak last year in his 750bhp RS200 with no dramas, we decided that would be the way to go.” So a new QBD3X sixspeed transmission was soon ordered and found its way on to the eagerly awaiting chassis. Designed as a direct replacement for the original unit, the Quaife ‘box easily fitted within the confines of the transmission tunnel without the need for a great deal of modification. At the front an uprated RS200 diff was retained, whilst at the rear the team opted to use a heavily modified Nissan Skyline differential. A pair of custom propshafts (both high and low speed units) and a set of custom driveshafts complete the beefed-up drivetrain.

The gearbox may have been mounted but it wasn’t time to forget about it, quite the opposite. “Setting up the paddle-shift function was probably one of the most time consuming parts of the project,” smirks Chris. The Life Racing pneumatic shift system uses compressed air to initiate gear changes, saving time and allowing the driver to keep both hands on the steering wheel at all times – but it does take time to calibrate correctly. As do many of the other incredibly complex functions the Life Racing ECU offers, such as the flyby-wire throttle system, knock control systems, air injectors, and multiple map settings. But once calibrated they all offer huge performance benefits. With all the electronics sorted and everything set up as it should be the rest of the car could be assembled.

And now that it is, there is just one thing left to do – race it! The RS200 is now ready to be loaded into the back of the race truck and head off to Mallorca where it’s due to compete in its first rally. “We are expecting to win it,” laughs Chris, “we won the same event in the Evo in the past, and this car is ten times better!” People often wonder what

rallying today would be like if Group B hadn’t been banned, and thanks to this RS200 we’ve got a pretty good idea – it would have been awesome!

Thanks Fast Ford for this amazing article.